Lead flashings are an integral part of the roof that prevent water from penetrating the building’s structure via joints. Flashings are commonly made from pieces of lead varying in thickness depending on the usage and average weather conditions, although alternative materials are also available.

Flashings have not always been a component when it comes to roofing, with other methods of keeping water out including angling tiles away from joints, building chimneys at the edge of the roof, and constructing steps into the side of the chimney. The use of lead dates to Roman times, when it was used during the construction of aqueducts between 500BC and 300BC, while Normans incorporated lead into the pipes, guttering and roof coverings.

What is the Purpose of Lead Flashing?

Quite simply, the purpose of lead flashing is to keep water out of the building. There are alternatives to lead flashings, with materials designed to mimic the function and appearance, but lead remains the standard across the industry.

Lead flashing has been used for hundreds of years. Without it, the roof is likely to develop leaks in sensitive areas that could have detrimental effects on the building’s overall structure. Refurbishment works to repair the damage left by leaks in roofs with either no or impeded flashings can be highly costly – far exceeding the costs of a roll of lead flashing.

Types of Lead Flashing

There are several different types of flashings, which are in accordance with their shape and location.

The types of flashings include:

- Roof flashing

- Wall flashing

- Sill flashing

- Roof penetration flashing

- Channel flashing

- Through wall flashing

- Cap flashing (also known as a drip cap)

- Drip edge

- Step flashing (commonly referred to as a soaker)

- Counter flashing

- Pipe flashing

- Chimney flashing

- Kickout flashing

- Valley flashing

Wherever flashing is installed, its primary objective is to move water away from the structure of the building. Incorrectly installed flashings can direct water directly into the building, which is worse than if there was no flashing in place. For this reason, it is essential that not only the correct material is used, but that it is installed by someone who knows what they are doing.

Why Lead Flashings are Popular

Lead flashings remain popular, despite the toxicity of the material, because the material has a lifespan of up to 500 years and is completely recyclable. Over 95% of lead used in the modern-day has been made from recycled materials, and three million tons of lead is recycled from scrap every year – further proof of the material’s ecological benefit.

Although the use of lead pipes has been banned in the UK since 1969, it is still a regular feature in roofing. The material is only dangerous for those who are in constant contact with it every day, which is why its use as lead flashings is still permitted, but contractors responsible for installation must follow strict guidelines. This includes wearing PPE and limiting the number of times they come into contact with the lead.

Lead flashings are the most efficient means of waterproofing joints in the roof, and they also remain the most aesthetically pleasing, often having a dark to light grey appearance. Listed buildings feature lead flashings as standard, with more new-builds also using lead due to its environmental advantages.

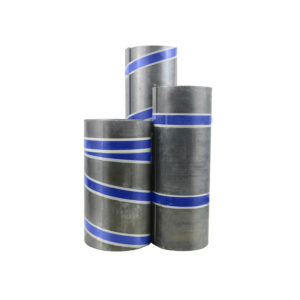

How Much is a Roll of Lead Flashing?

The cost of a roll of lead flashing is dependent on the code you are buying. Here at ERoofing, we stock codes 3 through to 8, with code 3 lead flashing being the thinnest and code 8 being the thickest. Prices are based on the cost of the lead, which stands at £2.40 per kg exclusive of VAT (at the time of writing) on bulk orders of 1000kg and upwards.

Code 3 lead flashing is the cheapest option but is nowhere near as robust as code 8 lead flashing and is usually used as a soaker. Depending on the location of the flashing and the average weather conditions it will be subjected to, different codes of lead flashings should be invested in. Not all codes can be used in all areas of the roof and listed/historical buildings are likely to require thicker rolls of lead flashing.

Are Lead Alternatives Viable?

At ERoofing, we do stock a range of lead alternative flashings that are designed to mimic the real thing. These generally come in two styles, smooth and textured, and is more cost-effective than real lead flashing.

As well as making for a cheaper option, another reason many opt for an alternative is that lead flashings, as a general rule, cannot be painted. This is because when lead oxidises it forms a white powdery substance and, when a layer of this forms, this causes paint to peel. Paint is also not recommended for lead flashings as the lead must be allowed to breathe, otherwise, its life expectancy is considerably reduced as the material will crack. Lead alternatives can be painted to suit the project.

A lead alternative flashing roll will also be easier and safer to cut than the real thing. A knife or a pair of scissors will suffice for cutting most rolls of lead alternatives.