Uses

This 700T Silicone by Everbuild is excellent for perimeter pointing internally and externally, with its robust, durable adhesive compatible with PVCu, wood and plastic, ensuring a secure bond on various application areas, one of the being window frames. The formula inside the 700T allows it to work well as a sealant for expansion joints and soft metals such as lead, copper and zinc.

Some of the surfaces that this product can adhere to are;

- PVCu

- Wood

- Plastic

- Lead

- Copper

- Zinc

- Plastic

Preparation

Ensure you properly prepare the surface before commencing the application and remove dirt, dust, oil, grease or other contaminants that can hinder the adhesion of this product.

If the application area is plastic, you should test the product's compatibility with the plastic in a small area before completing the full project, as different plastic react differently to this product.

To enhance adhesion to PVCu, you should prime it by wiping it with PVCu Solvent Cleaner or White Spirits (If painted, this doesn't include enamel paints, as the white spirit will strip the paint off)

This product should adhere to most surfaces. However, with the few that it doesn't, you must apply a primer first; if unsure, you can always test first in a small inconspicuous area.

Application

- Cut the top of the cartridge, ensuring you do not damage the threaded screw.

- Screw the nozzle onto the cartridge, and cut the nozzle at a 45° angle with an opening slightly larger than the area to be filled.

- Apply to the area, using a firm, even pressure on the gun to ensure an even bead is applied to the space creating a secure bond.

Limitation

- This product is not suitable to be used on bitumen, asphalt, neoprene and certain organic elastomer

- This product should not be used in the manufacturing of an aquarium

- Substrated that bleed oils, solvents or plasticisers are not suitable areas of application for this product

- This product is not suitable for paints to be applied over

- Not suitable for bedding

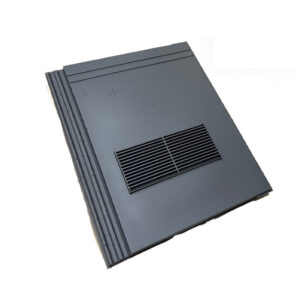

Ulti-Mate Stonewold Mk2 Roof Tile Vent - Grey

Ulti-Mate Stonewold Mk2 Roof Tile Vent - Grey  Code 8 Cast Lead - 760mm x 6m

Code 8 Cast Lead - 760mm x 6m  Everbuild Lumberjack 550 Floor Adhesive – Buff 300ml (Box of 12)

Everbuild Lumberjack 550 Floor Adhesive – Buff 300ml (Box of 12)  Everbuild Febond PVA - 2.5L

Everbuild Febond PVA - 2.5L  Code 6 Cast Lead - 914mm x 3m

Code 6 Cast Lead - 914mm x 3m  Bond It Lightweight Render Mesh - 50m x 1m (Pink)

Bond It Lightweight Render Mesh - 50m x 1m (Pink)  FloPlast Round 92½° Bend - Brown

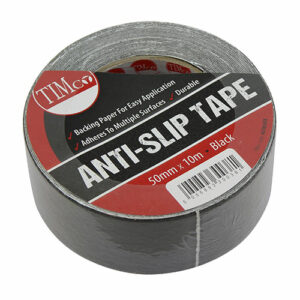

FloPlast Round 92½° Bend - Brown  Timco Anti-Slip Tape

Timco Anti-Slip Tape