Uses

Fix ALL X-Treme Power by Soudal delivers incredible bonding strength, with this formula able to support weight up to 400kg/m², it's one of the strongest adhesives available on the market. This product is ideal for those in the building, metal or automotive industry. This product's high-shear strength, flexible elasticity and general resilience against various weathering make it perfect for nearly most adhesive applications.

Some of the surfaces this product can adhere to include;

- Stone, Concrete, Marble, Granite, Limestone, Travertine, Cork, Rockwool, Gypsum board, Polystyrene, Glass, Mirror, Porcelain, Tiles, Brickwork, Steel, Stainless steel, Lead, Zinc, Copper, Aluminium, PVC, Polycarbonate, Wood, Timber, Plywood, MDF, Plasterboard, Fibreglass, and many more.

Preparation

Before starting the application, ensure you prepare the surface to aid you in achieving optimal adhesion. This includes removing dirt, dust, oil, grease and similar contaminants. If the surface is porous in a water-loaded application, you should prime it first.

Applications

- Cut the top of the cartridge, ensuring you do not damage the threaded screw.

- Screw the nozzle onto the cartridge, and cut it at a 45° angle

- Using a standard sealant gun, apply the adhesive in beads or dabs every 15cm, and ensure you cover the edges and corners of the surface

- Press the two surfaces together, using a rubber hammer to batten it down

- This product will take 24-48 hours to cure, and you can fully load it after

Limitations

- You can paint over with water-based paints; however, preliminary tests are suggested due to the large amount of paints available on the market. Not all are suitable for this product.

- Certain surfaces, such as plastics, polycarbonate, etc., must have preliminary tests completed before the entire project due to some substrates being unsuitable for this product.

- This product is unsuitable as a glazing sealant or in constructing aquariums.

- Not suitable for sanitary applications.

- Discolouration may occur due to chemicals' high temperatures of UV-radiation, but this won't affect the adhesive properties.

- Contact with bitumen, tar or other plasticiser-releasing materials, such as EPDM, neoprene, butyl, etc., are unsuitable for this product; it will cause discolouration and negatively impact the adhesive.

Hambleside Danelaw Double Roman Tile Vent, TV15/3 - Black (Box of 5)

Hambleside Danelaw Double Roman Tile Vent, TV15/3 - Black (Box of 5)  ALM Code 4 Milled Lead - 800mm x 6m

ALM Code 4 Milled Lead - 800mm x 6m  Everbuild Triple Action Wood Treatment – 5 Litre

Everbuild Triple Action Wood Treatment – 5 Litre  Bond It Bath Mate Bath & Kitchen Sealant - White EU3 Box of 25

Bond It Bath Mate Bath & Kitchen Sealant - White EU3 Box of 25  Everbuild Black Jack 908 DPM – 25 Litre

Everbuild Black Jack 908 DPM – 25 Litre  Code 5 Cast Lead - 1600mm x 6m

Code 5 Cast Lead - 1600mm x 6m  Everbuild Professional Sealant Gun – C4 (290 - 380ml)

Everbuild Professional Sealant Gun – C4 (290 - 380ml)  Everbuild P45 Foam Applicator Gun

Everbuild P45 Foam Applicator Gun  Code 3 Cast Lead - 760mm x 3m

Code 3 Cast Lead - 760mm x 3m  Ronseal Ultra Tough Mattcoat Clear Varnish - 2.5L

Ronseal Ultra Tough Mattcoat Clear Varnish - 2.5L  ALM Code 6 Milled Lead Flashing - 760mm x 6m

ALM Code 6 Milled Lead Flashing - 760mm x 6m  Code 7 Cast Lead - 850mm x 6m

Code 7 Cast Lead - 850mm x 6m  FloPlast Square Line External Stop End Black – 114mm

FloPlast Square Line External Stop End Black – 114mm  ALM Code 7 Milled Lead - 510mm x 6m

ALM Code 7 Milled Lead - 510mm x 6m  Bond It A70 Studlock Anaerobic High Strength Adhesive - 50ml Green

Bond It A70 Studlock Anaerobic High Strength Adhesive - 50ml Green  Bond It Rain-Mate All Weather Sealant - White EU3

Bond It Rain-Mate All Weather Sealant - White EU3  FloPlast Half Round Line Pipe Socket, White

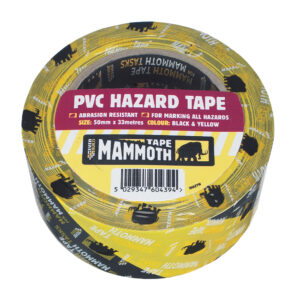

FloPlast Half Round Line Pipe Socket, White  Everbuild PVC Hazard Tape - Black/Yellow (50mm x 33m)

Everbuild PVC Hazard Tape - Black/Yellow (50mm x 33m)