Flashing Tape

-

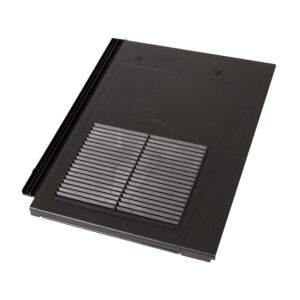

Klober Thin Line Vent – KG9855-3 (Various Colours)

From: £32.39 Incl VAT £26.99 Excl VAT Select options This product has multiple variants. The options may be chosen on the product page -

Code 6 Cast Lead – 760mm x 6m

£391.27 Incl VAT £326.06 Excl VAT Add to basket -

JCB Grey Heel and Toe Socks

£7.85 Incl VAT £6.55 Excl VAT Read more -

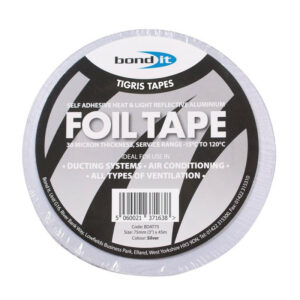

Bond It Aluminium Foil Tape – 75mm x 45M

£8.99 Incl VAT £7.49 Excl VAT Add to basket -

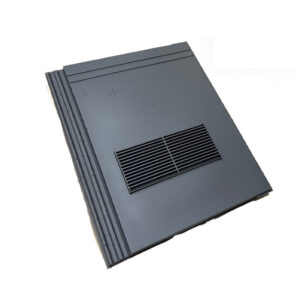

Ulti-Mate Stonewold Mk2 Roof Tile Vent – Grey

£59.99 Incl VAT £49.99 Excl VAT Add to basket -

Thompson’s 10 Year Roof Seal – 1L

From: £17.99 Incl VAT £14.99 Excl VAT Select options This product has multiple variants. The options may be chosen on the product page

Flashing Tape

Roofing flashing tape, also known as flashband or lead flashing tape, is one of many ways to protect, repair, and watertight seal something permanently. Due to its heat resistance and ability to provide an immediate watertight seal on an enormous variety of surfaces, it is an essential part of any roofing project. In addition, it comes in multiple sizes to suit your roof needs.

Among our range, we have the excellent Cromar Flashing Tape, Bostik Flashing Tape and Everbuild’s flashing trade tape.

How To Apply Flashing Tape the Correct Way

To help out, here is a short guide on how to apply flashing tape.

Cut the Flashing Strip to the length required. To avoid any creasing, remove approximately 50mm of backing paper and carefully position the sealing strip. Hold the backing paper firmly and release it steadily from the sealing strip as the product is applied.

Smooth into position using hand pressure. Use a seam roller or rounded wood smooth to ensure good contact and expel any air, especially on overlaps and at the edges. When laying adjacent rolls, Flashing Strip should be overlapped by a minimum of 25mm for a watertight seal.

The seam must be pressed firmly with a hand roller paying particular attention at the point of overlap. Remember, if applying this in cold weather (5-15 Celsius), storing the flashing tape in a warm place is highly recommended before use. If possible, it is also suggested to warm up the surface slightly.